3D printing revolution

I just completed the two week 3D printing revolution course. Week one was a good overview of what 3D printing is, while week two highlighted applications of 3D printing. I took a 3D printing class at Duluth Maker Space two years ago and completed a small project. My opinion at the time was that it is a crude tool suited for hobbyists and incapable of manufacturing retail products. I must admit that the course altered my opinion significantly and now I believe that 3D printing is indeed revolutionary.

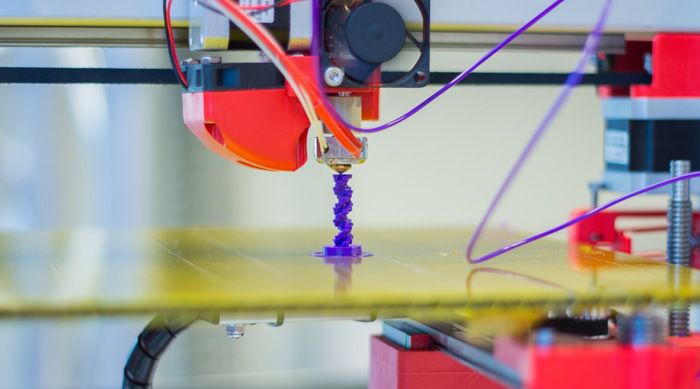

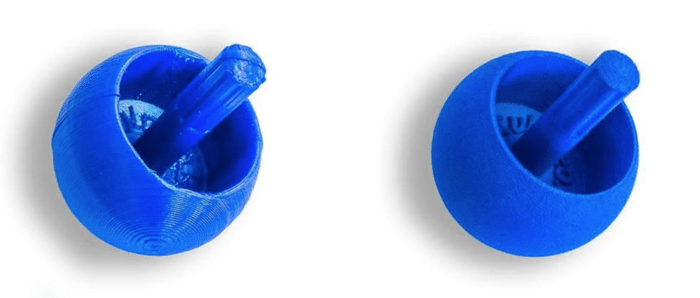

The first thing that swayed my opinion is that there are many different methods of printing, some of which can produce well polished products. Previously I was only aware of Fused Deposition Modeling (FDM) which is analogous to squeezing plastic toothpaste out of a small tube in progressive layers to create a 3D object. This leaves a crude layered finish on a product. However, Stereolithography (SLA) and Selected Laser Sintering (SLS) in nylon can produce a much smoother finish. FDM on the left and SLS on the right:

Many items around the house now seem within the capability of an SLS printer. SLS printers are too expensive to own outright, but are available through services like shapeways.com. Send them your digital design and Shapeways will print it for you in professional plastic, steel, aluminum and more. Wow.

The second revolutionary aspect of 3D printing is its digital nature. Objects are represented as digital files. A good analogy is music. It used to sell on cassettes and CDs that record companies produced. Now music is digital, stored at low cost and accessible anywhere in the world instantly. Recording music can be done using a laptop and a good quality microphone and then uploaded to Soundcloud or Youtube where it’s accessible to virtually anyone in the world. 3D printing brings these same characteristics to objects. You can browse a digital marketplace and when it’s time to checkout, your purchase gets printed locally/instantly instead of being shipped from a warehouse. No inventory is required. I can see a future where Amazon just stocks their distribution centers with raw materials and printers, only manufacturing objects at the time of purchase. Because the cost of entry into the market is bound to be very low, advertising will likely become the main form of revenue. For example, you can have the digital file for free is you watch a 60 second ad and then print it yourself at the cost of materials.

The final property of 3D printing that revolutionizes the manufacturing process is that printing a personalized product is very cheap. There is the up front work of altering the design but this can be automated to an extent. For example, imagine being able to imprint your name on any object you own. I’ve always wanted a TED cup that I could keep using throughout the day and easily distinguish from others’ cups. While plastic injection molding is incredibly fast, it is unable to produce customizations without incurring significant cost. Assuming (and this is a big assumption) that 3D printing speed can be accelerated by several orders of magnitude, it would have a huge advantage over traditional manufacturing methods. If 3D printing remains slow, people may be willing to pay more for items customized for their specific needs.

I’m currently working my way through Makers and planning to read Fabricated as well. The course recommended both books as a good overview of the potential of 3D printing technologies. Even if the reality of 3D printing fails to meet the revolutionary hype, it has already demonstrated its value for weekend hobbyists and inventors alike.